High-temperature melt pump plays a key role in industrial production, and its spiral sealing technology is an important guarantee to ensure the efficient and stable operation of the equipment. High-temperature melt pump spiral sealing principle is mainly based on dynamic sealing mechanism, the core lies in the use of gear shaft operation, the sealing sleeve bore of the multi-head helical groove generated by the counter-thrust, effectively preventing the conveying medium to the shaft leakage, and thus achieve excellent sealing effect. The following is a detailed explanation of this working principle:

High-temperature melt pump spiral seal principle in-depth analysis

(A) the core role of dynamic sealing

Spiral seal as a unique dynamic sealing method, highly dependent on the continuous rotation of the gear shaft to maintain its sealing performance. When the gear shaft begins to rotate, the multi-head spiral groove in the sealing sleeve will play a guiding role, so that the conveying medium follows a specific path of flow, which generates a strong counter-thrust in the process, becoming the key force of the seal.

(B) the subtle formation mechanism of the counter-thrust force

Spiral groove has been carefully designed so that the medium in the flow of inward pressure. This pressure and media leakage outward tendency is just the opposite, the two counterbalance each other, the formation of an effective way to prevent the leakage of the counter-thrust. With the uninterrupted rotation of the gear shaft, the counter-thrust continues to accumulate and strengthen, as a solid barrier, a strong barrier to prevent the conveying medium to the shaft out of the overflow, to ensure the reliability of the seal.

(C) Stable maintenance of sealing effect

As long as the gear shaft keeps rotating, the spiral seal can continuously generate counter-thrust, thus maintaining a good sealing effect. This dynamic sealing method has excellent self-adaptation, can keenly perceive the changes in media pressure and flow under different working conditions, and automatically adjust the sealing performance to adapt to the complex and changing working environment.

The applicability of high-temperature melt pump spiral seal and key considerations

(A) a wide range of applicability

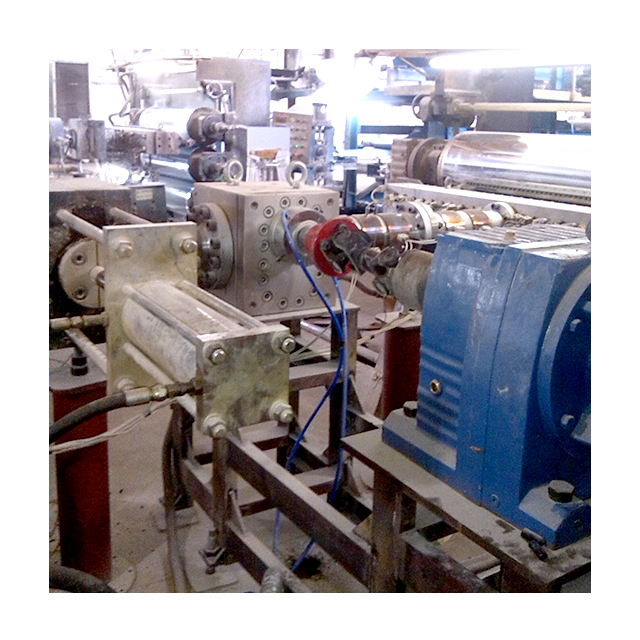

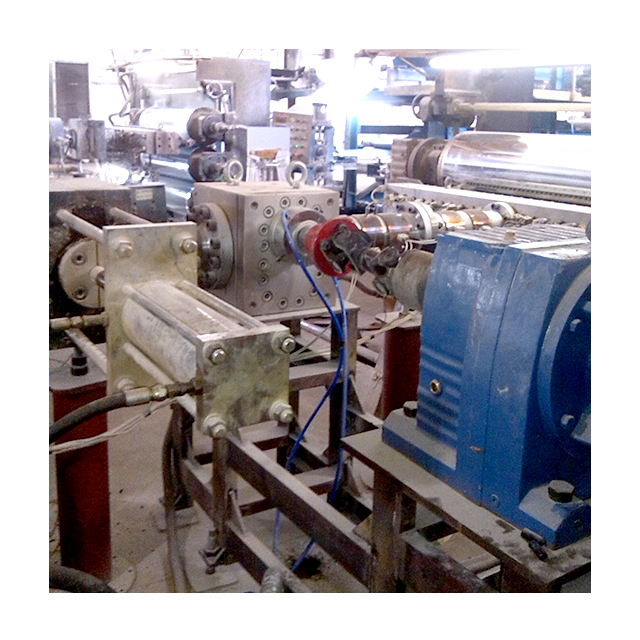

Spiral seal in the high-viscosity melt and inlet pressure is positive dynamic sealing scenarios with excellent performance, has a unique advantage. In the practical application of high temperature melt pumps, it is often used to resist high temperature, high viscosity polymer melt leakage problems, to provide a solid guarantee for the stable operation of the equipment.

(B) should not be overlooked precautions

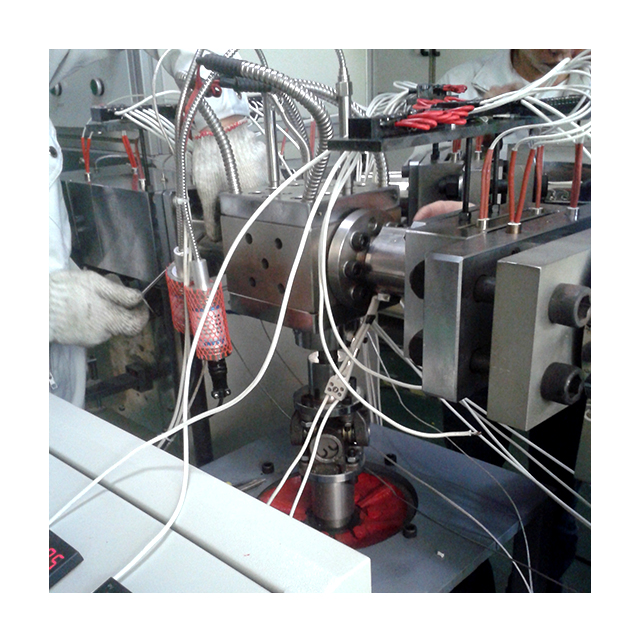

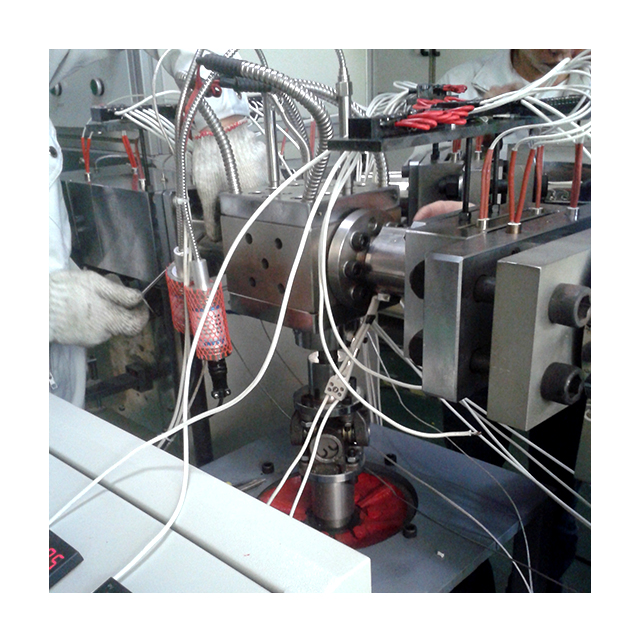

When high-temperature melt pumps convey low-viscosity polymers such as PP, PE and PS, it is recommended that a cooling jacket (or cold water plate) be installed at the shaft end in order to further improve the sealing effect. By lowering the melt temperature, the viscosity of the melt medium is increased, which significantly enhances the sealing performance. In addition, the sealing effect of the spiral seal is also affected by the design parameters of the spiral groove (such as groove depth, groove width, helix angle, etc.) and the nature of the medium (such as viscosity, temperature, pressure, etc.). Therefore, in the actual application process, must be based on specific working conditions, the spiral seal for accurate selection and careful adjustment to ensure that it is always in the best working condition.

To summarize, high temperature melt pump spiral seal through the gear shaft rotation, sealing sleeve bore multi-head spiral groove formed by the counter-thrust, effectively preventing the leakage of the transport medium. With its dynamic adaptability, self-sealing characteristics and excellent sealing effect and other significant advantages, this sealing method has been widely and successfully applied in high temperature and high viscosity polymer melt conveying equipment, providing strong support for the efficient and stable operation of industrial production.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447