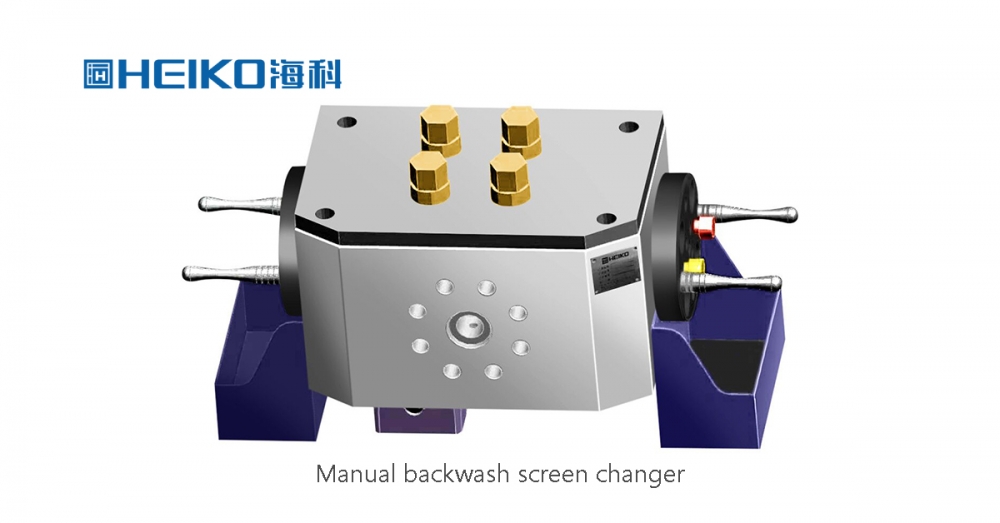

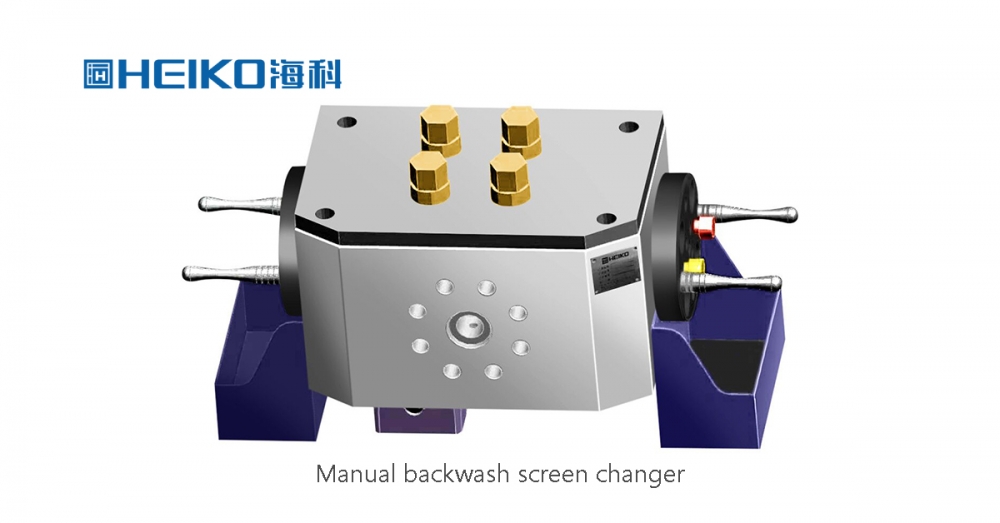

Core functions of manual quick screen changer

Filtering impurities: Its main function is to filter the high-viscosity melt, filtering out foreign particles and impurities in the melt, so as to improve the purity of the melt and ensure the quality of the subsequent products. For example, in the plastic extrusion production, it can remove the foreign matter in the raw material and prevent the products from defects.

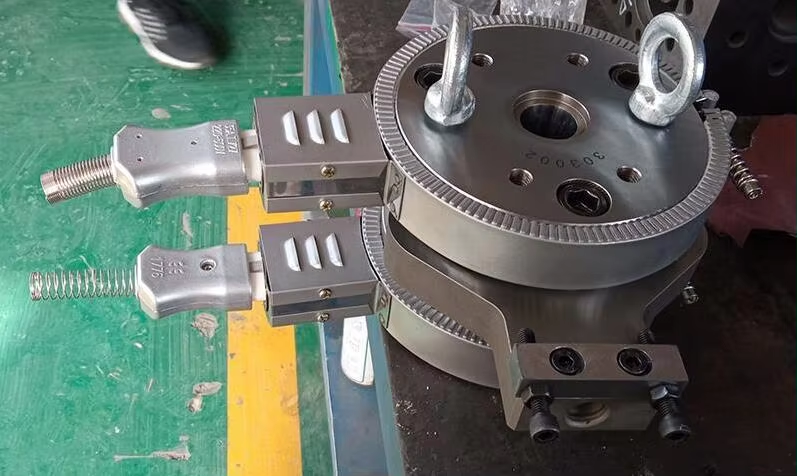

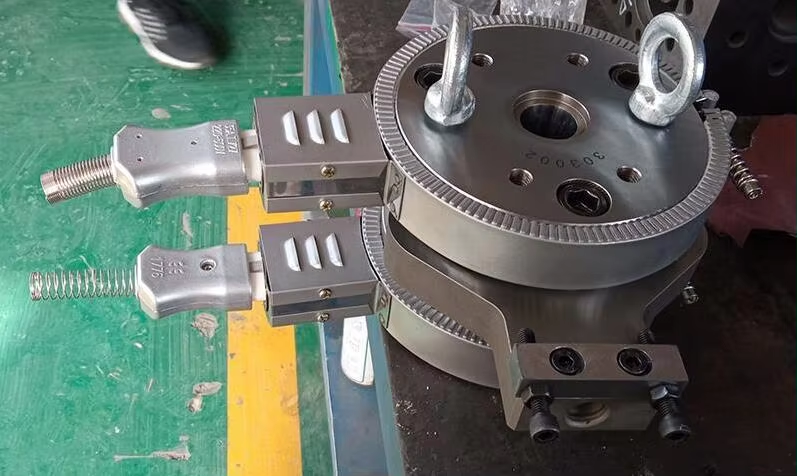

Quick screen changer: equipped with two filtering stations, when the screen in one station needs to be replaced due to excessive accumulation of impurities, the station can be quickly removed from the main body through manual operation, and at the same time, the other station to be filtered into the main body of the screen changer, thus realizing the quick switching of the screen, and reducing the interruption of the production due to the change of the screen.

Advantages of manual quick screen changer

Easy to install: no need for complex external control systems, the overall structure is relatively simple, the installation process is simple and fast, can be quickly installed on the extrusion line and other equipment.

Simple operation: the operator can master the screen changer operation after simple training, only need to trigger the handle after deceleration or stop to complete the screen changer process, easy to get started.

Compact size: It does not occupy too much space, which is very suitable for enterprises with limited production space, and can be flexibly installed in various extrusion lines.

Good sealing effect: the unique flexible sealing device can ensure good sealing performance during the filtration process, preventing melt leakage and ensuring the quality and purity of the material during the filtration process.

Accurate positioning: accurate positioning during screen changing ensures smooth flow of materials and avoids production interruption or quality drop caused by filtration problems.

Cost-effective: Compared with more complex and expensive equipment such as automatic screen changers, manual quick screen changers are less costly, making them an affordable choice for small and medium-sized enterprises with limited budgets.

Strong applicability: the operating lever can adjust its position according to the spatial condition of the production site, which can adapt to different production environments and spatial layout requirements, and is suitable for a variety of high-viscosity melt extrusion lines, such as the production of drip irrigation tapes, cast film production, blown film production, and the production of hollow products.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447