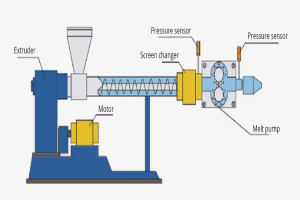

High-temperature melt pumps are specialized industrial equipment designed for conveying high-temperature, high-viscosity molten materials. They are widely used in industries such as plastics, rubber, synthetic fibers, and food processing. Their core function is to stably convey molten polymers, metals, or food slurries under high-temperature (typically 200–400°C) and high-pressure (up to 50 MPa) conditions, ensuring the continuity and stability of the production process. Compared to ordinary pumps, its design must overcome challenges such as material thermal deformation, seal failure, and medium degradation.

Key Technologies and Structural Design

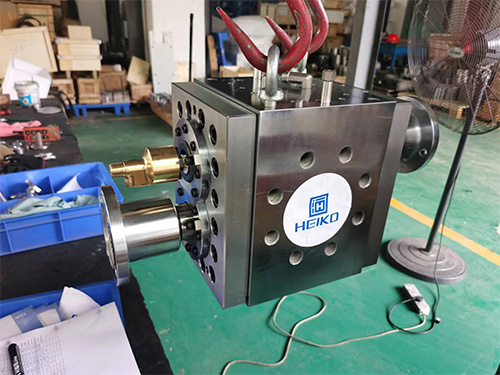

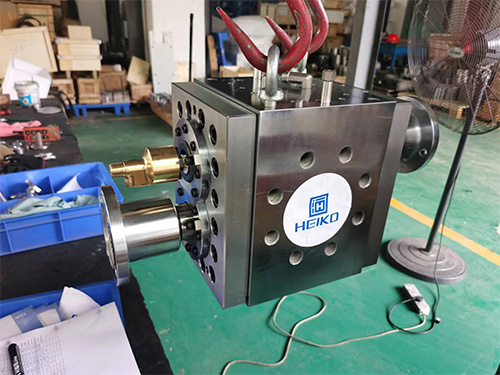

High-temperature melt pumps adopt a modular design, primarily comprising the following core components:

1. High-temperature-resistant gear system: Utilizes special alloy steels (e.g., H13 tool steel) or surface nitriding treatment to maintain geometric precision at high temperatures;

2. Dynamic sealing device: Combination mechanical seals (such as double-ended cartridge seals) paired with an inert gas barrier to prevent melt leakage;

3. Temperature control system: Integrated electric heating rods and liquid thermal oil circulation channels achieve precise temperature control within ±1°C;

4. Flow channel optimization: Low-shear streamlined design reduces the risk of material thermal degradation.

Industry application scenarios

1. Plastic extrusion: In PET sheet production, the melt pump can control extruder output pressure fluctuations within ±0.5%;

2. Chemical fiber spinning: Stable delivery of molten polyester to prevent fiber breakage;

3. Food industry: High-hygiene standard transportation of high-viscosity foods such as chocolate and syrup;

4. New energy sector: Precise metering of molten electrolyte in lithium-ion battery separator coating processes.

Selection and Maintenance Considerations

Users should select models based on medium characteristics (viscosity, corrosiveness), flow rate range (0.1–200 m³/h), and operating pressure. Key maintenance points include:

1. Regularly replace high-temperature resistant lubricating grease (such as perfluoropolyether grease);

2. Inspect gear meshing clearance every 500 hours;

3. Thoroughly remove residual melt during shutdown to prevent carbonization and blockage.