1. Basic Structure and Sealing Method.

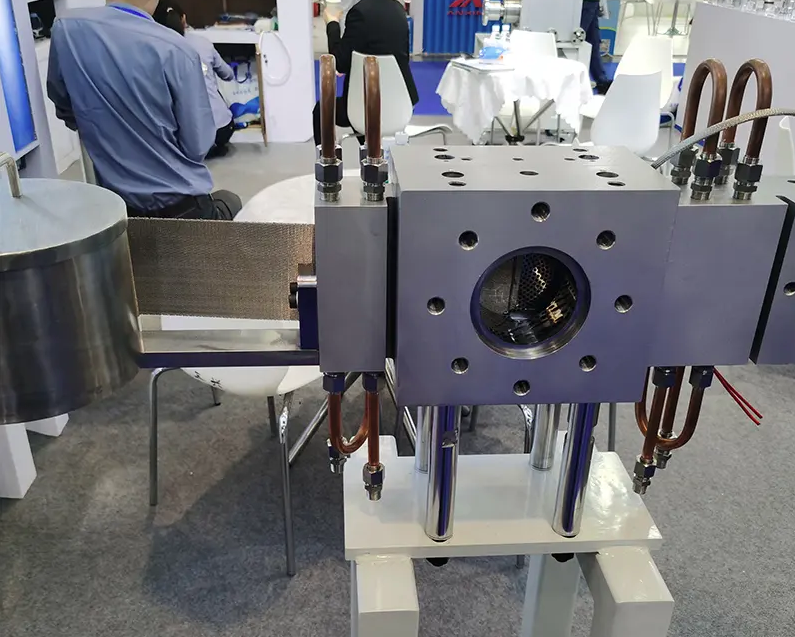

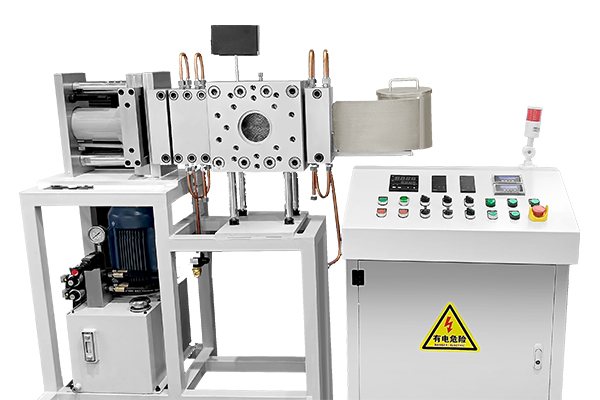

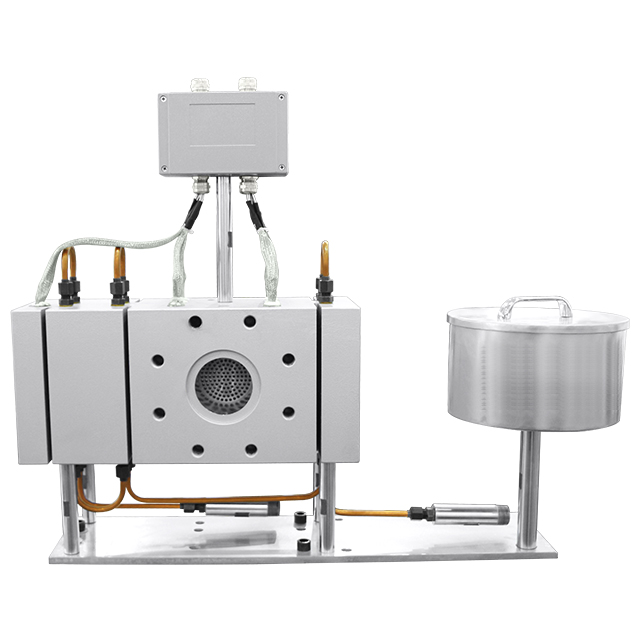

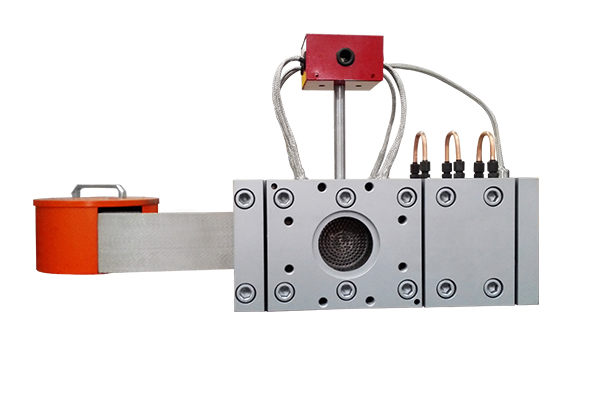

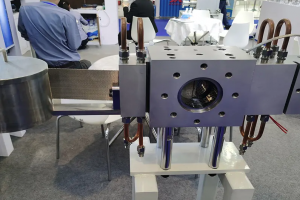

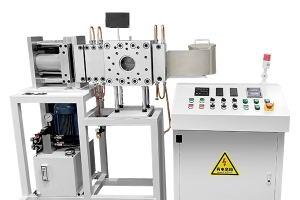

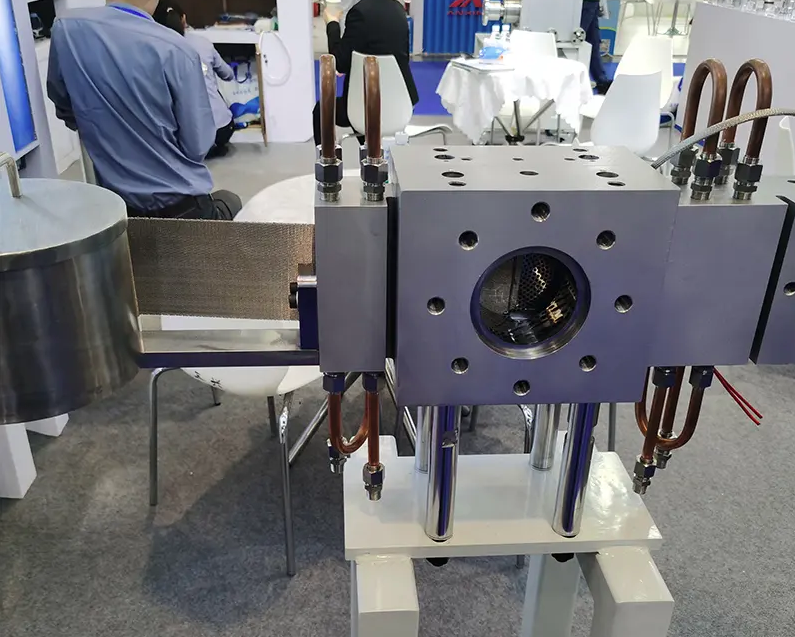

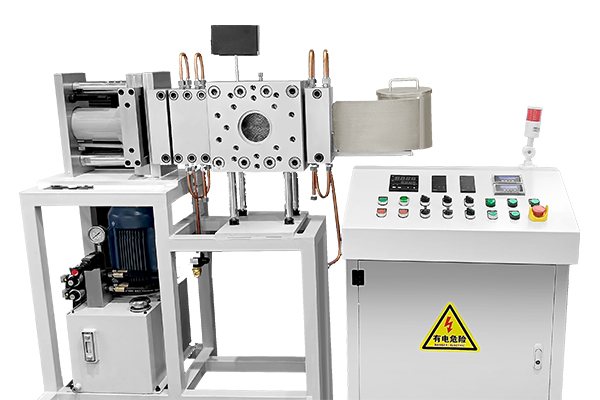

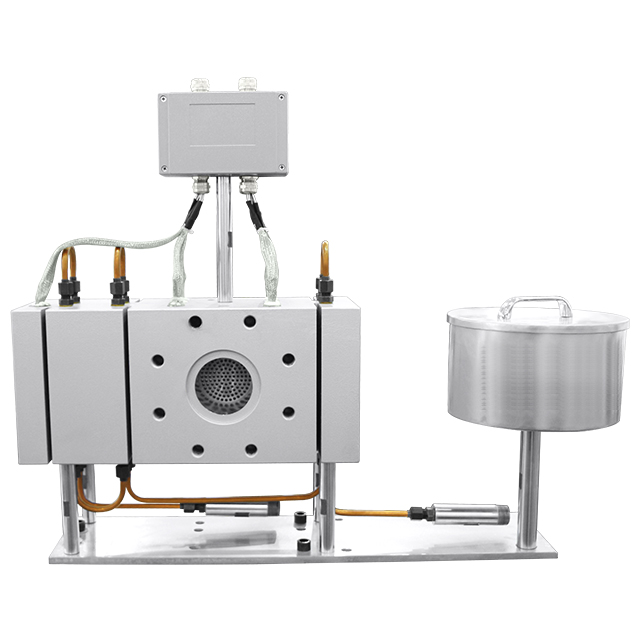

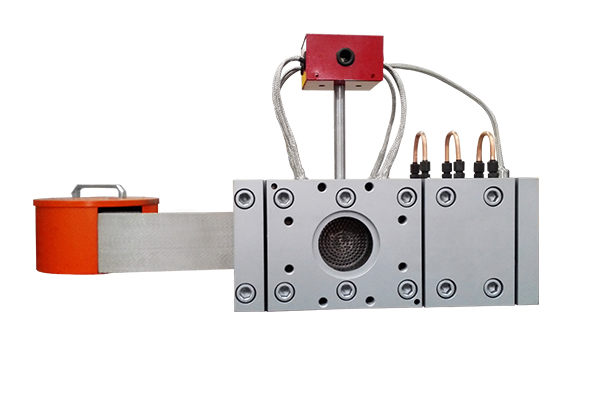

Structural Components: The belt-type automatic screen changer primarily consists of a mesh-type contrast belt, a filter screen box, an inlet cooling section, a main flow channel connection section, an outlet cooling section, and an electrical control system.

Water-Cooled Sealing: Water-cooled sealing is employed to ensure no melt leakage during operation. This sealing method effectively prevents high-temperature melt leakage, ensuring production safety and stability while minimizing raw material waste and environmental pollution.

2. Screen-changing action trigger mechanism.

Melt pressure trigger: During production, when the melt pressure at the feed port of the screen changer reaches the pre-set value, it triggers the screen-changing action. As production progresses, impurities in the melt gradually accumulate at the filter screen, causing the feed port pressure to rise. When the pressure reaches the set value, the control system automatically initiates the subsequent screen-changing procedure.

Time-controlled triggering: In addition to melt pressure triggering, the screen change operation can also be controlled based on a pre-set time interval. When the set time interval is reached, the control system will initiate the screen change operation even if the melt pressure has not yet reached the set value. This method is suitable for production scenarios where melt pressure fluctuations are minimal but regular filter screen replacement is required.

3. Screen-changing process.

Heating: After the screen-changing action is triggered, the control system automatically activates the heating rods at the outlet end of the filter screen belt to initiate heating. The purpose of heating is to raise the melt temperature at the outlet end to a level that allows the filter screen to move smoothly, thereby removing impurities from the melt along with the filter screen as it exits the screen-changing device.

Screen Change: Once the outlet end reaches the set temperature, the filter screen begins to move automatically under the pressure of the melt itself. Since the filter screen in the belt-type automatic screen changer is continuous, uninterrupted filtration is achieved during the screen change process, ensuring continuous production.

Cooling and Sealing: As the filter screen moves, impurities are carried out of the screen changer, causing the pressure at the screen changer's inlet to gradually decrease. When the pressure drops to the normal operating value, the control system stops heating the electric heating rods at the outlet end. At this point, cold water is circulated through the outlet end to cool and solidify the melt, thereby achieving sealing and preventing melt leakage.

4. Continuous operation.

After completing one mesh movement operation, the belt-type automatic mesh changer continues filtration until the conditions for mesh movement are met again, repeating this cycle to achieve fully automatic mesh changing.

In summary, the belt-type automatic screen changer utilizes melt pressure or time control to trigger the screen change action, offering advantages such as automated screen change processes, minimal fluctuations in material pressure and flow, and excellent product quality stability. It is primarily used in the production of high-quality, long-process products such as chemical fiber spinning, filament drawing, pipe manufacturing, film blowing, cast film, lamination, sheet production, film production, pelletization, and other high-quality, long-process manufacturing applications. It is particularly suited for the production of high-precision products with strict requirements for pressure stability.